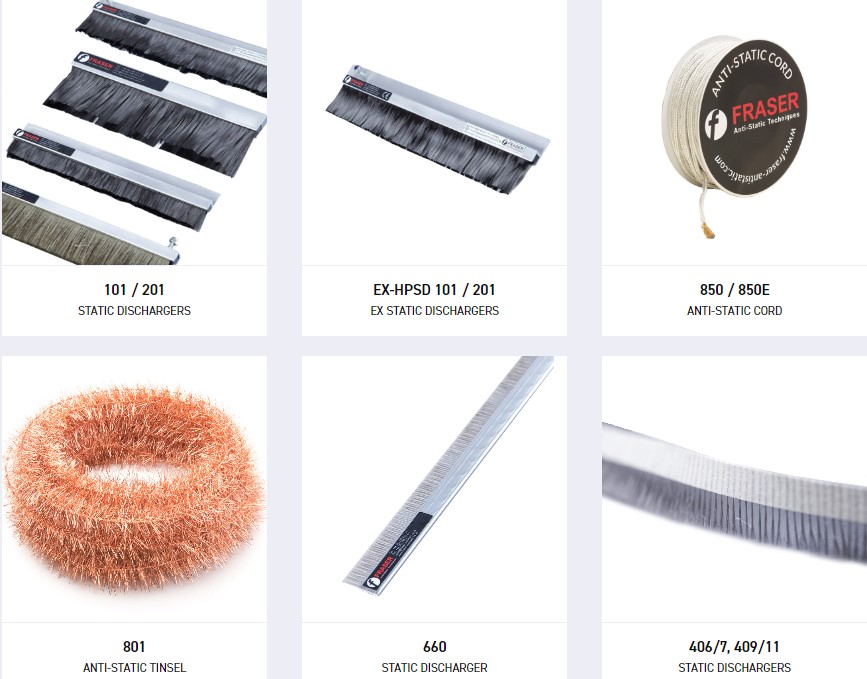

This Web page provides easy access to product brochures, information on static electricity and how it can be measured, removed or generated in specific applications.

We understand the electrostatic challenges that new materials, faster speeds, complex machinery and advances in industrial processes can present.

Static issues in packaging can be costly and wasteful. They can prevent packages from filling correctly, forcing product to misbehave. Static can also create sealing issues and numerous problems with label printers and applicators, shrink wrappers, containers and webs.

We work with companies in the plastic production, plastic converting, moulding, printing, and others

Static can be an issue in injection moulding, thermoplastics, blow moulding, vacuum forming, paint spraying, rubber and extruded parts.

Ensuring that plastic components are static and dust-free before painting or sealing is particularly critical for reasons of quality and cost control.

There are few plastics manufacturing processes that do not suffer adverse effects from the build-up of static charges. Many benefit from controlled static generation to temporarily bond two materials in a process.

Printing on paper or plastics in high-speed, sheet and web fed applications will create static control problems. These issues apply to offset, gravure, flexographic, screen, pad, inkjet, laser and digital printing processes.

Static electricity can cause print quality issues, as well as sheet feeding and delivery problems. It can also create a risk of fire in solvent processes.

Once used mainly for electronics and medical applications, cleanrooms are increasingly used in many areas of plastics processing.

These include injection moulding, extrusion, converting and assembly. Static control is vital in all of these areas

There are many processes in the manufacturing of medical equipment, pharmaceuticals, nutraceuticals and biotech products that generate static electricity.

These issues are compounded by low humidity and the flammable nature of some of the solvents and fine powders used.